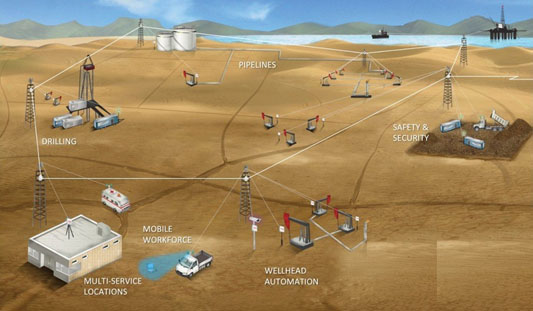

TAJ LLC understands the operator’s need to increase surveillance and condition monitoring of the production wells requirements to establish remote control, automation and surveillance of well heads over Radio communication. INTAJ has the experience, technology and a proven track record that enables us to provide a high-level requirement for the radio Frequency planning and scope of work associated with design, engineering, supply, software upgrading and configuration, site installation, testing and deploying of the Automation and Network to the production wellheads (for existing, and future drilled wells) as well extending the coverage of communication and increasing Access point’s throughput at field to support multimedia and control systems. For better reservoir management, well data and control is required for Company RMT for close monitoring and surveillance of production wells.

INTAJ provides planning, assistance in construction and deployment of an Automation and Surveillance system with a wireless Network coverage to the Production Wellheads in Production fields by utilizing the Radio at 5.6 – 5.8GHz. This Radio frequency is license free for industrial use. The project will extend the coverage of the Radio communication to the production Wellhead. Extension coverage is to debottleneck any existing network and add further required Access Point to support the added Automation and Surveillance systems.

In order to have the optimized communication based on the field condition, INTAJ customizes its proposals to take into account installation of different level towers, repeaters and execute Radio Frequency (RF) plan for an entire field. This also includes the installation of connecting AP to the fiber optic backbone of the automation and IT networks (Base tower).

Radio spectrum is a scarce resource and therefore this activity includes various methods and processes to optimize and spare channel bandwidth by reducing the channel. Decreasing the wireless communication channel size from 20 MHz to 10 MHz will add more capacity per tower which is Ideal for adding multimedia surveillance.

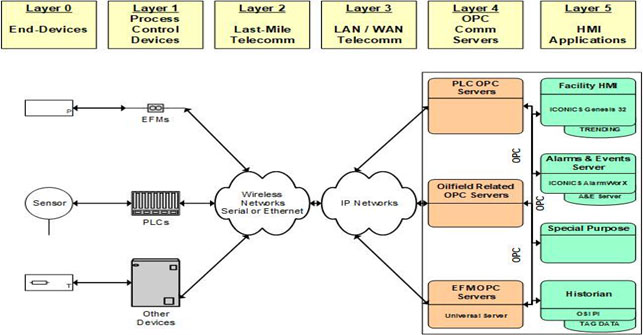

RTU systems can interface with other PLCs, POCs, EFMs, ESP Controllers. Below is an illustration of the flow of data from the field devices to the final corporate historian and SCADA systems.